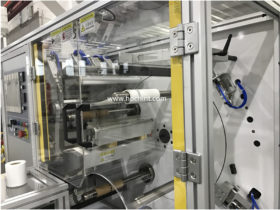

DG-330 Label Rewinding Collecting Machine

- Paper tube vibrating tray

- Automatic paper feeding device

- PLC and touch screen control system

The turret re-winder system uses the world famous brand BOSCH. It has features of automatic paper feeding , paper releasing, automatic rewinding and automatic unloading functions. It improve production efficiency and save manual labor.

√ one year guarantee √ 24 hours technology support √ engineer available for installation

The machine is equipped with a vibrating plate automatic paper feeding tube mechanism,a discharge mechanism. The whole machine is automated to realize online non-stop rewinding, to improve production efficiency and reduce manual labor.

Features:

- The rewinder can be connected with printing press, die-cutting machine, slitting machine and other equipment, from the top tube to roll. and then to unload a molding.

- It is equipped with 1 inch ,1.5 inch, 3 inch interchange gas expansion shaft.

- Change the size of different rolls, do not need manual mechanical adjustment, different size touch screen automatic adjustment.

- Reduce labor intensity, improve efficiency and achieve intelligent production.

| Model | DG-330 | DG-380 | DG-330 |

| Max. winding diameter(mm) | 350 | 350 | 350 |

| Max. input paper width(mm) | 330 | 380 | 520 |

| Min. winding width(mm) | 40 | 60 | 100 |

| Total power(kw) | 8 | 10 | 12 |

| Power supply | 3PH+N+PE | 3PH+N+PE | 3PH+N+PE |

| Overall dimension(mm) | 1450*3000*1700 | 1450*3200*1700 | 1450*3500*1700 |

| Weight(kg) | 2000 | 2100 | 2200 |

| Pressure(MPA) | 0.8 | 0.8 | 0.8 |

- Paper tube vibrating tray Auto paper feeding device

- PLC touch screen system Coiling machanism

Leave A Comment