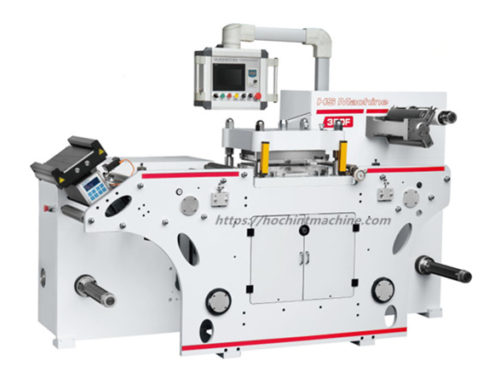

HCM-320 Flatbed Die Cutter(multi-function)

- Die cutter and sheet cutter

- Hot foil stamping function

- Hole punching function(longitudinal)

This machine, based on the standard flatbed die cutter, is equipped with foil stamping device. It can either be used for die cutting or foil stamping. The innovative hot stamping unit is compatible with the whole flatbed press. It enables foil to move through the press in sequence using servo motor with high precision.

√ one year guarantee √ 24 hours technology support √ engineer available for installation

Foil hot stamping

Platen die cutting

Hole punching

Sheet cutting

Main features as follows:

- Foil stamping unit is equipped and foil feeding adopts servo motor.

- PLC from Mitsubishi (Japan) and touch screen for easy operation.

- Material-feeding is controlled by servo motor.

- three electrical sensors, two for web guide system and one for color tracking, make the web in right position.

- Magnetic powder clutches control the tension of rewinding and waste rewinding.

| Model | HCM-320 | HCM-420 |

| Max. web width(mm) | 320 | 420 |

| Max. unwinding diameter(mm) | Φ600 | Φ600 |

| Max. rewind diameter(mm) | Φ600 | Φ600 |

| Max. die-cutting area(mm) | 300*300 | 400*400 |

| Position precision(mm) | ±0.10 | ±0.10 |

| Max.Die cutting speed(times/min) | 300 | 200 |

| Power supply | 380V & 3 phase | 380V & 3 phase |

| Total power(kw) | 4 | 5 |

| Weight(kg) | 1700 | 2300 |

| Overall dimension(mm) | 2600*990*1400 | 2600*1450*1400 |

- Color tracking sensor(Italy) Web guiding sensor

- Servo motor for pulling Waste collecting

- Sheet cutting device Magnetic clutch for rewinder

- PLC (Mitsubishi, Japan) Color touch screen

Leave A Comment