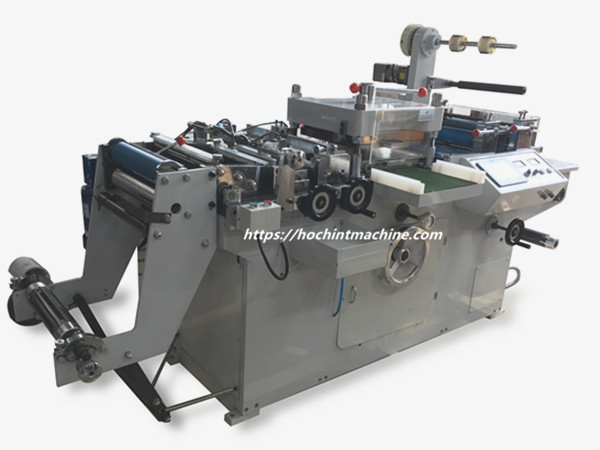

HCM-320 Label Platen Die Cutting Machine

- Servo motor for pulling

- PLC and touch screen control

This is suitable for die cutting adhesive paper label, dacron film label and laser anti-false label. It cuts label materials into shape required for a designated shape design with high precison. The die cutting, film laminating, waste rewinding, sheet cutting(or roll rewinding) can be finished in one process.

√ one year guarantee √ 24 hours technology support √ engineer available for installation

Main features as follows:

- PLC from Mitsubishi (Janpan) and touch screen for easy operation.

- Material-feeding is controlled by servo motor.

- Double photoelectric sensors for web-guiding.

- The machine adopts Schneider (France) low power appliance.

- The mechanical speed could be 300 times/min.

- Waste rewinding tension is contolled by magnetic powder clutch

Respect to various industries demands, we provide customized options to complex products to be completed in one run.

- film laminating device

- foil stamping device

- hole punching device

| Model | HCM-320 | HCM-420 |

| Max. web width(mm) | 320 | 420 |

| Max. unwinding diameter(mm) | Φ600 | Φ600 |

| Max. rewind diameter(mm) | Φ600 | Φ600 |

| Max. die-cutting area(mm) | 300*300 | 400*400 |

| Position precision(mm) | ±0.10 | ±0.10 |

| Max.Die cutting speed(times/min) | 300 | 200 |

| Power supply | 220V or 380V | 380V |

| Total power(kw) | 4 | 5 |

| Weight(kg) | 1700 | 2300 |

| Overall dimension(mm) | 2600*1350*1400 | 2600*1450*1400 |

- Color tracking sensor(Italy) Web guiding sensor

- Synchronous belt Die cutting section

- Servo motor for pulling Waste collecting

- Sheet cutting device Magnetic clutch for rewinder

- PLC (Mitsubishi, Japan) Color touch screen